Replacement Stepper Motors and Light Bulbs for 2003-2006 GM Instrument Clusters

- Regular price

- $29.95

- Sale price

- $29.95 Sale

- Unit price

- /per

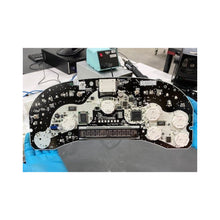

03-06 Instrument Cluster Gauge Motor and Lights

Genuine OEM (Original Equipment Manufacturer) GM stepper motors. These are the very latest revised and updated GM factory stepper motors specifically designed to be a 100% cure for the common problems seen in 2003-2006 General Motors vehicles such as sticky needle movement, jumpy readings, dead gauges, gauges that ratchet up or down, gauges pegged out to the left or right of the dial and more.

- 7 Genuine OEM GM Stepper Motors.

- 12 Genuine light bulbs and base.

- #1 RATED GM STEPPER MOTOR REPAIR KIT - Set of 7 Genuine Switec OEM GM Stepper Motors, part number x27.168 (not aftermarket).

- Most GMs have six gauges and you'll need one motor for each gauge in your instrument cluster to complete the job. While you're in there you may as well replace all the stepper motors because they're all guaranteed to go out eventually. Once one goes out it's not long before the rest go too!

- COMPLETE KIT - Includes 7 motors. Fits ALL 2003, 2004, 2005, and 2006 Chevrolet GMC Silverados, Suburbans, Tahoes, Trailblazers, Yukons, and more.

GM Stepper Motors

General Motors are the industry standard in terms of precision and reliability. With a wide range of sizes and options available, they have just the right stepper motor for your application.

Instrument panels, navigation systems, infotainment displays – stepper motors from GM provide accurate and repeatable positioning for the automotive industry’s most advanced information displays.

Instrument clusters, on the other hand, require the utmost in design flexibility. That’s why GM stepper motors are available in a wide range of sizes, shapes, and various options to meet the needs of even the most challenging applications.

Can a stepper motor be repaired?

Yes, but only very rarely. Stepper motors that develop problems are typically replaced. Typically, repair consists of replacing the motor itself.

Motors should be replaced in pairs. Original stepper motors installed in the Cray-1 and some other early supercomputers were made by Hitachi. Replacements for these motors are still available from several sources, including the original manufacturer.

A soldering iron can be used to replace the windings in a stepper motor, but this is not recommended for most users. Careful! The iron can damage the insulation on the wires, causing a short.

How do I reset my Chevy gauge cluster?

Gauge cluster reset procedures are unique to each manufacturer. For Chevrolet vehicles, the best way to reset the gauge cluster is to disconnect the battery for at least 30 seconds. This will allow the vehicle's computer to reset and should fix the problem.

Gauge repair may be necessary if the needles are damaged or broken, or if the backlighting is not working properly. In some cases, the entire gauge cluster will need to be replaced.

On the account of safety, it is always best to consult with a professional if you are having trouble resetting your Chevy gauge cluster.

What does stepper motor do?

A stepper motor is a device that converts electrical energy into mechanical motion in discrete steps. It may lack some of the nice features of a servo motor, such as speed and position feedback.

They also do offer unique features which make them attractive in particular applications. Fuel gauges in cars provide a good example of the unique benefits offered by a stepper motor.

In the United Kingdom, a variant of the stepper motor is called a 'switched reluctance motor'. These were formerly manufactured by Siemens.

What is a stepper motor on a gauge?

A stepper motor is a device that converts electrical energy into mechanical motion in discrete steps. It may lack some of the nice features of a servo motor, such as speed and position feedback.

Stepper motors do offer unique features which make them attractive in particular applications. Oil pressure gauges and temperature gauges use stepper motors for this reason. The water temperature gauge uses a variable reluctance device as do some other gauges such as the speedometer.

The whole cluster may be replaced if the stepper motor fails. A new one may be needed if the oil pressure or water temperature gauge is not functioning properly.

How do stepper motor gauges work?

Stepper motor gauges use a stepper motor that consists of six magnetic poles. The rotor for this device is attached to the needle on your instrument cluster and as current passes through the coils, it creates a magnetic field. This causes the rotor to align itself with the magnetic north of the field which in turn acts against a spring and moves the needle.

Battery voltage gauge uses a different approach. Instead of using a stepper motor, the voltage gauge uses a rheostat to vary the amount of current allowed to flow through the coil in the sender unit attached to your battery. This works exactly like turning up and down an electric heater with a knob. As you turn it up, it draws more current which results in the needle moving up on your gauge.

Make sure to check the installation instructions that came with your new stepper motor before you explore any further. Some manufacturers have very specific installation requirements that must be followed to the letter in order to avoid any damage to your new purchase.

Are all GM Stepper motors the same?

No. GM stepper motors are classified as "A", "B" or "C" series depending on the year they were made. They are not interchangeable. "A" Series stepper motors used in early cars will not work in later models and vice versa. In addition, if you change the type of stepper motor (C to A, B to A, etc), you must also change the wire harness that attaches to it. Soldering iron and crimp-on terminals are required to do this.

Transmission temperature gauge is another example where a different approach is used. This time, instead of using a stepper motor, the Transmission temperature gauge uses a thermistor.

Instrument panels that use a thermistor instead of a stepper motor can be found in some late model cars. The advantage to using a thermistor is that it can be placed in the transmission where it can get a more accurate reading of the transmission fluid temperature.

How does instrument cluster work?

GM instrument clusters are an array of lights and gauges hooked together with a main printed circuit board (PCB). The printed circuit boards make the inside of your instrument cluster look similar to a computer motherboard. The components on the board are very precise and must be installed in just the right direction for everything to work right.

The actual gauges (temperature, speedometer, fuel, etc) are typically replaced because they get old or broken rather than fail completely. Instruments that work intermittently may actually be failing and just giving you a false reading. Bad solder joints or corrosion on the PCB can do this as well.

General Motors has used many different types of stepper motors over the years. The most common are the A, B, and C series. These stepper motors were used in a variety of applications such as oil pressure gauges, water temperature gauges, and battery voltage gauges. You can find the correct stepper motor for your car by matching the series letter and the part number on the old stepper motor.

What is a stepper motor gauge?

A stepper motor gauge is a device that indicates to the driver of a vehicle important information about any aspect of the vehicle. This can include fuel level, speed, temperature, etc. A Stepper motor is a type of stepping motor that uses steps to move in fixed angular increments. Original stepper motors installed in the instrument cluster make a loud clicking sound as it moves to the desired position.

While this is an effective method of moving the needle, it is not very accurate and does not provide any feedback to the driver when that position has been reached. Stepper motor gauges are able to move their needles much more precisely (with less noise) because they use a different type of technology to operate. This results in a more reliable system that provides the driver with better feedback.

A clear lens covers the stepper motor and the needle is mounted on a shaft that passes through the center of the lens. The lens magnifies the needle so that it is easily visible to the driver. The stepper motor is mounted on a circuit board that is located behind the lens. It is connected to the needle shaft with a toothed belt or gear.

Can stepper motors be repaired?

Yes. GM stepper motors can be repaired provided you have the patience to do so. Soldering skills are required along with wire crimping tools and access to a volt/ohm meter.

It is not possible to just replace the motor but you can carefully remove it from your old cluster and attach it to your new one if all else fails. You should be able to find a similar motor at any auto parts store such as AutoZone, Advance, or O'Reilly's.

The best way to ensure your safety while driving is to know the signs of a failing stepper motor so that you can take action before it fails. Intermittent power failure is the main cause of stepper motor failure. If you are having issues with your stepper motor, it is best to just replace it.

How do I reset my GM instrument cluster?

GM vehicles are equipped with an out-of-tolerance warning light that indicates the cluster has failed in some way. If your fuel or temperature gauge is no longer working, this lamp may be lit up which tells you to shut off your car immediately and get it checked out by a mechanic.

When this happens, the cluster must be reset which can be accomplished by turning on the ignition switch and holding down the trip odometer button while you turn on your key. After this happens, all gauges (except fuel and temperature) should work and go off of their own accord within a few seconds of driving. Direct replacement or aftermarket clusters typically do not require any type of resetting once installed.

Replacing a GM instrument cluster is not an easy task. It should only be undertaken by experienced technicians since it requires the removal of several components including the speedometer itself. This can be very difficult depending on which vehicle you are working on and if all necessary parts are available to make this replacement happen correctly. The entire process could take up to six hours depending on the vehicle. Disconnecting all of the wires is extremely important if you do not want to cause damage or create electrical shorts which could result in serious injuries.

How does a stepper motor gauge work?

The stepper motor gauge works with a printed circuit board that has a specific number of lights and gauges attached to it. The printed circuit board controls how much power is allowed to go through the coil inside the sender unit on your fuel tank or anywhere else for that matter. As current passes through, it creates a magnetic field which causes the sender unit to move up or down.

The fuel level in your tank will dictate how far this unit will travel, which tells the gauge how much fuel is in your tank. The trans temp gauge operates in much the same way, but it will require a different sender unit.

Repair kit costs:

- GM Instrument Cluster Repair Kit (Non-Stepper Motor) – $95.00 GM Stepper Motor Repair Kit – $140.00 + $20.00 refundable core charge

- GM Instrument Cluster Repair Kit (Non-Stepper Motor) – $95.00 GM Stepper Motor Repair Kit – $140.00 + $20.00 refundable core charge

- GM Instrument Cluster Repair Kit (Non-Stepper Motor) – $95.00 GM Stepper Motor Repair Kit – $140.00 + $20.00 refundable core charge

How does a stepper motor increase speed?

GM stepper motors have a gear reduction system that increases the RPM of the motor itself. The fuel level in your tank will dictate how much power is being used which limits the speed at which the sender unit can travel up and down. If you put more fuel in your tank, it tells the gauge to send more voltage through which allows for a higher speed. In other words, as long as there is enough current going through, you might as well use all of it so you get a higher reading on your gauge.

As GM stated, "Peak performance comes from using both hands; one to drive and one to read the gauges". The odometer screen will also give you a cumulative total of how many miles or kilometers you have driven since the last reset.

This is convenient if you want to keep track of your average fuel economy or how long it takes you to get from one destination to another. The stepper motor is a key component in making sure that your gauge readings are accurate.

What is a stepper motor good for?

Stepper motors are good for anything that needs to be accurately controlled electronically. They can also handle more power than your average linear motor or servo motor and are useful in many applications such as robotics where you need precise control of the motor to get things done right.

Instrument panels, fuel gauges, and other automotive applications are perfect for stepper motors because they need to be accurate and they can handle the power required by these types of applications.

This item is also good for money because it will save you time and effort in the long run. You will be able to use your car for a longer period of time without having to replace the entire system.

Can a bad instrument cluster cause battery drain?

A bad instrument cluster can cause battery drain in two ways. The first is when the power is being sent to the wrong part of the motor which may result in abnormal readings or no reading at all. This will cause your vehicle to turn off after a few minutes due to an out-of-tolerance warning light. GM recommends resetting this faulty unit to get it working again.

The second way is when the power isn't getting to the coil on the fuel sender unit resulting in no current flowing through which means your car won't start at all. This is a more serious issue and will require some investigation to find the root cause.

It's important to have your instrument cluster repaired as soon as possible to avoid any further damage to your car.

What type of motor is a stepper motor?

A stepper motor is a type of brushless electric motor that has a rotor that can be positioned to specific locations when you apply the right currents to the coils in its stator. Each winding in the stator can be used as an electromagnet. If you put electricity through two adjacent windings at any given time, a magnetic field is created which makes the shaft turn.